Flow and Volume

Initial Concentrations (g/ml)

Bacteria Concentration

Chemical Constants (1/day)

Bacteria Growth Rate

Light Intensity Constants

Final Simulation Time

Process Overview ...

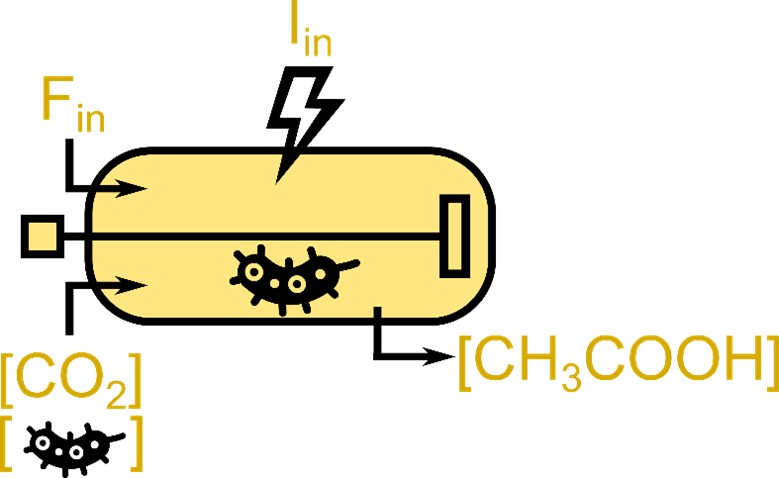

The process simulates CO2 recycling through the biochemical conversion facilitated by Moorella thermoacetica and cysteine (CyS), producing acetic acid as a final product. The reaction follows the equation:

CO₂ + 2 C₃H₇NO₂S (CyS) → CH₃COOH (Acetic Acid) + C₆H₁₂N₂O₄S₂ (CySS)

This simulation can be performed using either a Batch Reactor or a Continuous Stirred-Tank Reactor (CSTR), depending on the user’s selected parameters. The maximum reaction time per simulation is set to 24 hours (1 day).

To estimate the annual production, the simulation runs 365 cycles of 24-hour reactions, calculating daily production and conversion efficiency. The final annual production is determined by summing the results of all individual simulations.